Many clock owners find that winding and setting their clock each week is a special and enjoyable part of their routine. Is it for you? Maybe you have owned a clock for years and have wound it hundreds of times. You have always taken care to wind each spring up slowly making sure you don’t go too far, since you were warned by your parents or grandparents not to overwind the clock!

So, when the day comes that you wind your clock and it stops or breaks, the first thing you think is that it must your fault! “I think I’ve over-wound my clock!” is the most common thing we hear from customers visiting our clock repair shop. But how common is it to really over-wind a clock?

What actually happened to your mainspring?

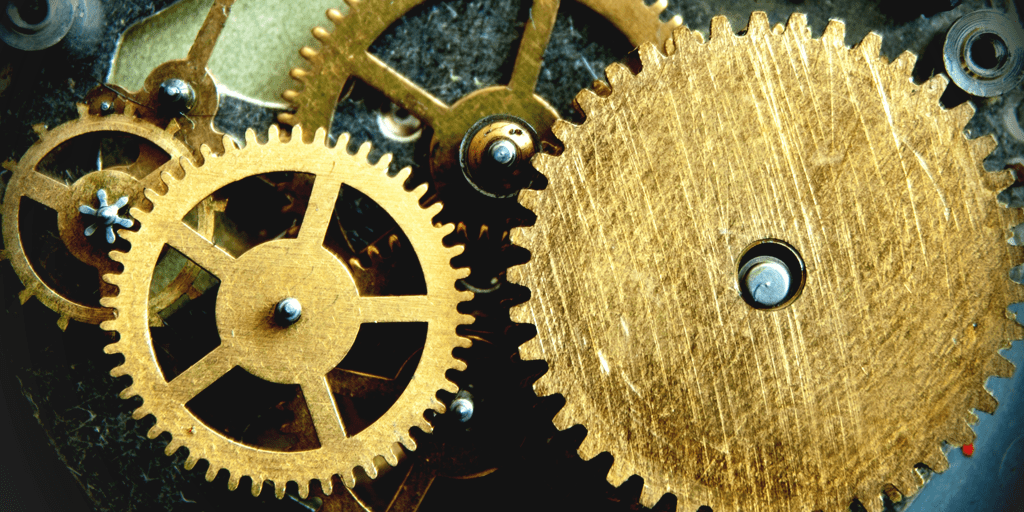

Luckily, the truth is that you can’t over-wind your clock. Over-winding is basically a myth! Let’s take a look at what actually causes a clock to quit running or chiming after winding it up… A clock mainspring is made of spring steel and is about the width of a ruler (but not quite as thick). They are on average 7 to 8 feet long! One end of the mainspring hooks on a winding arbor (the thing your key goes onto when you wind it). The other end hooks onto either the inside of a drum or on the corner post of the clock movement.

A mainspring must be fairly clean and have a proper lubricant (typically grease) in order to wind and unwind easily (therefore delivering power). Over the years, the grease will become dry and sticky, and the mainspring may become rusty or corroded. These factors cause friction in the movement of the spring coils. Eventually the spring becomes so dry and gummy that is can’t release anymore, or the spring metal becomes worn out and corroded and may break!

How do we fix it?

If we suspect mainspring troubles in your broken clock, the first thing we do is remove the mainspring from the clock movement. We then determine if we can clean and lubricate it or if we have to replace it. We have special tools and equipment here in our repair shop for handling all sizes of mainsprings. It can be very dangerous to remove a powerful steel spring from a clock mechanism, so please don’t try to do it yourself without proper tools and training. The image above shows some of the special equipment we use to unwind and remove mainsprings (note the gloves for safety!).

If you’re having mainspring issues, it’s also a good indicator that we should clean and inspect the rest of the clock at the same time.

Taking care of your mechanical clock

Mechanical clocks do need to be handled with care and can be sensitive, but you shouldn’t have to be fearful of winding your clock. Because of this fear, some of our customers do not wind their clocks enough (and you don’t want to have to wind the clock twice a week or more)! When you do wind your clock, just make sure you have a tight fitting key and that it is inserted all the way. Turn the key slowly and just a half turn at a time. Wind it up until it stops. Do not try to force it to wind any further. Even though it is impossible to over-wind your clock, it is also not necessary to wind it until the last possible click of the ratchet. This may cause cracks over time at the end of the mainspring.

Credited to: https://tulsaclocks.com/clocks