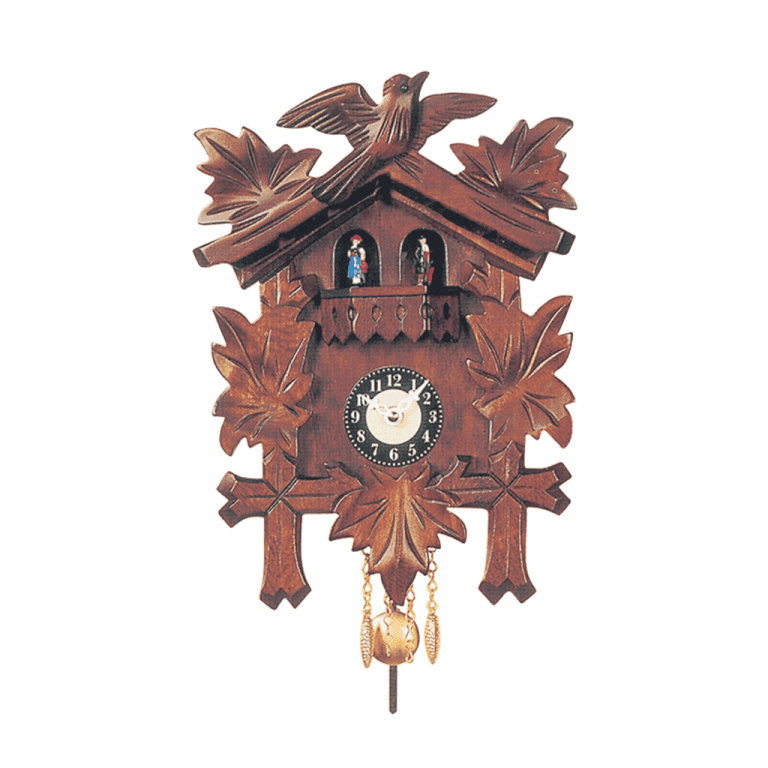

We rely on the accuracy of digital electric clocks — but many of us still have a mechanical clock or two around the house, perhaps an heirloom grandfather clock, mantle clock, anniversary clock, or cuckoo clock. This Fix-It Guide on mechanical clock repair tells how a mechanical clock works, what often goes wrong, how to identify a mechanical clock problem, and what parts and tools you will need to fix it. It then gives simple step-by-step instructions for how to clean a mechanical clock and how to lubricate a mechanical clock. Such care can extend a mechanical clock’s lifetime. See the Electric Clock Fix-It Guide for help in repairing an electric clock.

How Does a Mechanical Clock Work?

A clock is an instrument for measuring and displaying time. Mechanical clocks are driven by spur gears that are powered by either a falling weight or an unwinding spring that turns the hands at a precise rate. The main shaft then turns the hour, minute, and sometimes second hands around the clock face to indicate current time.

What Can Go Wrong with a Mechanical Clock?

Clocks can fall or be knocked over and damaged–sometimes beyond repair. However, most clock servicing is done because the mechanical clock isn’t telling accurate time anymore. It’s slowing down or has stopped. This is a preventable condition.

How Can I Identify a Mechanical Clock Problem?

Most mechanical clocks will run for many years before needing professional service such as replacing worn gears or springs. You can lengthen the time between professional servicing and even the life of your timepiece by keeping it lubricated (see below). Just make sure you don’t over-lubricate it. You also can clean it (see below).

What Do I Need for Mechanical Clock Repair?

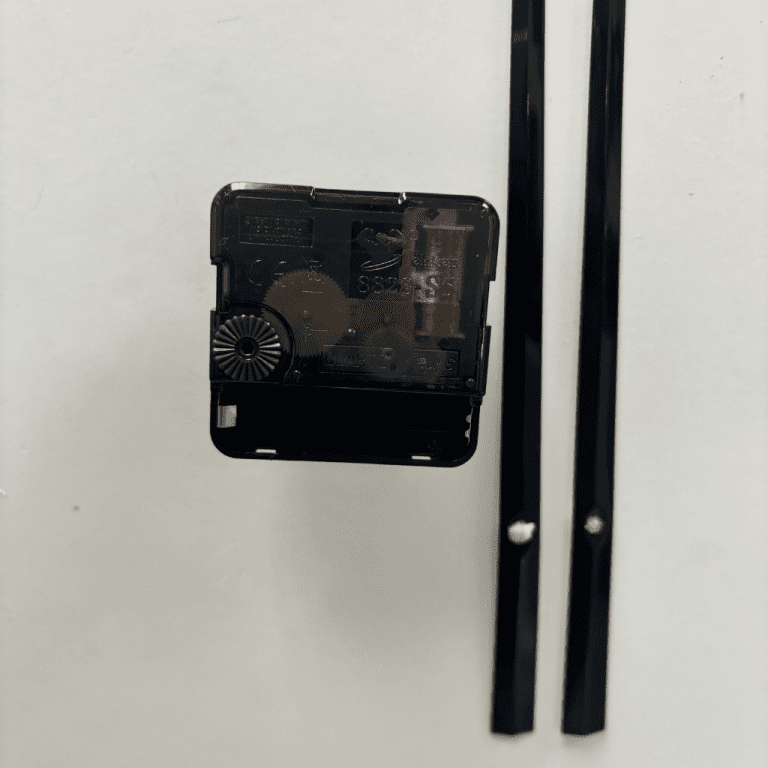

Some replacement parts for mechanical clocks are available from the manufacturer and aftermarket suppliers. In addition, you can find mechanical clock faces, hands, weights, keys, and other components at larger craft stores and some hardware stores. The tools you will need to fix your clock include these:

- Small screwdrivers

- Small wrenches or nut drivers

- Turpentine or paint thinner

- Small brush

- Empty coffee can

- Lightweight household (sewing machine) oil

What Are the Steps to Mechanical Clock Repair?

To clean a mechanical clock:

- Carefully remove the clock mechanism from the case.

- Pour a cup or two of turpentine or paint thinner in an empty coffee can or similar metal container.

- Place a small-mesh screen or cheese cloth over the top of the coffee can and, if necessary, secure it to the can with a rubber band around the can’s perimeter.

- Set the clock mechanism securely on top of the can so the chemical vapors reach the internal parts.

- Allow the vapors to work on the clock mechanism for at least 12 hours before removing. Carefully use a small brush to remove any debris.

- Lubricate the clock (see below).

To lubricate a mechanical clock:

- Carefully remove the clock’s back cover to access the interior of the clock. Some models require that the clock mechanism be removed from the case.

- Visually locate the working gears in the clock. If possible, wind the clock and watch it run for a few minutes to determine which are moving parts.

- Use lightweight oil to lubricate gear shafts sparingly. Wipe away excess oil.

- Replace the clock back or the mechanism in the case.

Credited to: fixitclub